How to Avoid Costly Kitchen Disposal Repair in Houston

A kitchen disposal is one of those quiet conveniences you don’t think much about until it groans, stalls, or starts throwing half-chewed lettuce back into the sink. In Houston, where summer heat accelerates odors and our clay-heavy soil makes plumbing shifts more common than folks realize, neglecting a disposal turns into a smelly, expensive problem faster than you’d expect. You don’t have to become your own plumber to reduce the odds of a big bill. A few habits, some local know-how, and a sense of what a disposal can and cannot do will keep your sink humming and your budget intact.

Why Houston’s conditions matter more than you think

Plumbing behaves differently in Houston compared with drier or cooler regions. Our high humidity makes odors bloom. Long stretches of 95-degree days turn forgotten food residue into a science experiment. Older neighborhoods inside the Loop have galvanized or cast iron pipes patched to PVC over decades, which means sharper bends and some quirky transitions that snag debris. In newer suburbs, builders often installed contractor-grade disposals rated for lighter use. Add in our city’s periodic heavy rains that nudge foundations and can tweak pipe slopes just enough to slow drainage, and a small disposal misstep becomes a clog at the trap or even farther down the line.

Professionals who do Kitchen disposal repair Houston wide see recurring patterns. They’re rarely about “mystery failures.” Most begin with choices at the sink that don’t seem harmful at the time, combined with equipment that’s either underpowered or poorly installed.

The anatomy of a healthy disposal

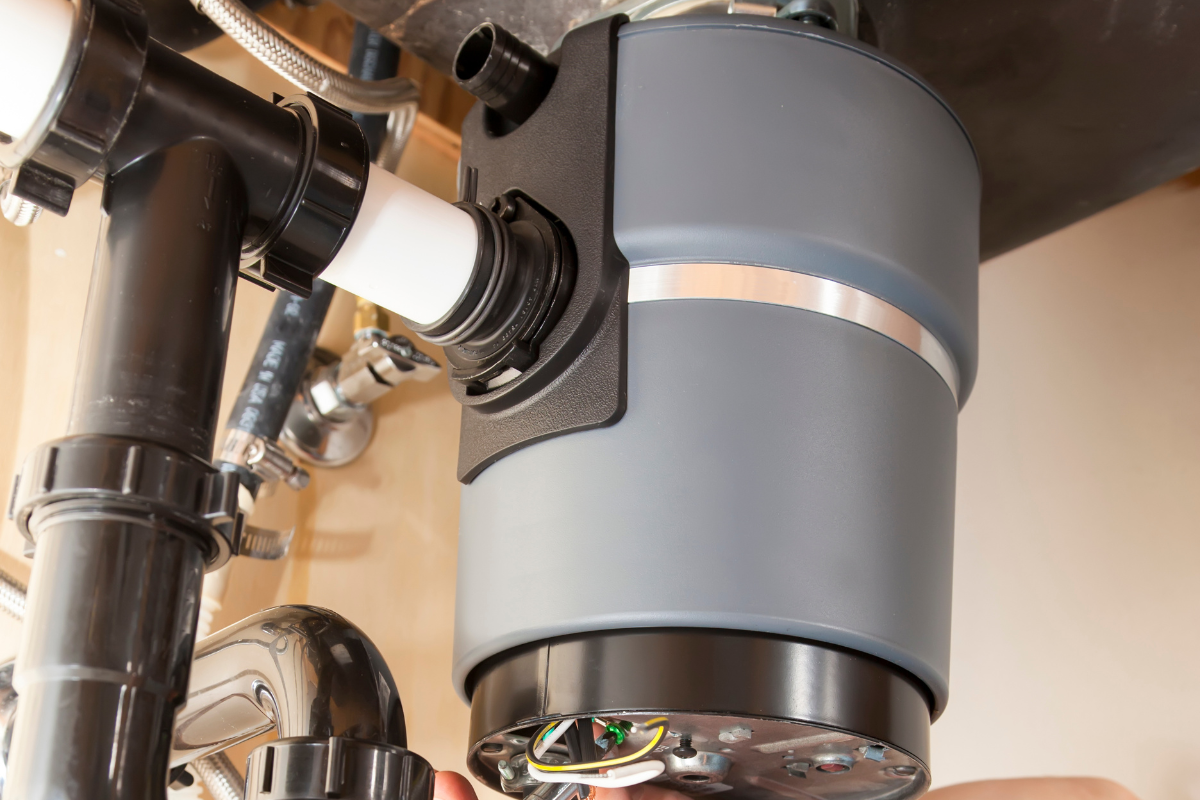

Understanding what the machine is and is not helps you use it wisely. A modern residential disposal does not contain slicing blades. Inside, you’ll find a spinning plate with two or more swiveling impellers. When you flip the switch, the impellers fling food against a stationary grind ring that breaks it into slurry. Water is not optional. It’s the conveyor that pushes the slurry past the ring and into the drain.

A half-horsepower unit is the compact sedan of disposals. It’s fine for a one-bedroom apartment with modest cooking, but it bogs down in a family kitchen that processes cereal bowls, fruit peels, and the aftermath of Sunday fajitas every week. A three-quarter horsepower model handles most households without complaint and includes better sound insulation, which matters in an open-plan home. One horsepower units grind nearly anything an average cook should send down a drain, but they weigh more, require a sturdier mount, and sometimes need a dedicated circuit. Choosing the right size is the first preventative step toward Affordable Garbage disposal repair later, since undersized motors overheat and fail early.

Everyday habits that keep repairs at bay

If you remember nothing else, remember this: cold water before, during, and after. Run the tap for a few seconds before you switch on the disposal, keep it flowing while you feed it, then let it run another 10 to 15 seconds once the grinding stops. Cold water keeps fats solid so the impellers can fracture them into smaller pieces before they enter the line. Hot water melts grease, sends it farther, then it resolidifies on cooler pipe walls, especially in air-conditioned spaces. That’s how you get a slow drain that becomes a packed clog.

Don’t treat the disposal like a trash can. The unit is designed for soft food scraps, not the entire end-of-meal contents of a roasting pan. Stringy items like celery, onion skins, leeks, corn husks, and artichokes behave like a mop head; they wrap the impellers and stall the motor. Starchy foods cause their own trouble. Mashed potatoes, pasta, and rice swell and turn into paste that coats the grind chamber and trap. Coffee grounds act like silt. A small amount isn’t catastrophic, but a daily espresso habit, rinsed straight into the drain, builds a dense layer that slows flow. Eggshells do not sharpen anything inside. They break into flakes that bind with grease and soap to form a gritty paste. Fruit pits, bones, and seafood shells are a hard no. They stress bearings, scar the grind ring, and can lock up a motor instantly.

Odor control takes persistence, not gimmicks. Citrus peels can help, but only in small pieces and with plenty of water. A better routine is a weekly flush with a full sink of cold water and a few drops of dish soap. Fill the basin, pull the stopper, switch on the disposal, and let the surge scrub the walls of the chamber and the drain line. If the rubber splash guard looks shiny with residue, lift it and scrub both sides. That flexible flange harbors most of the smell, not the grind chamber.

What “affordable” looks like in real numbers

Nobody wants surprises. In the Houston market, a straightforward Garbage disposal repair for a jammed unit often falls in the 100 to 180 dollar range if it’s a simple reset or jam clear, assuming no parts are needed. If replacement is required because the motor windings are shot or the housing leaks, expect a basic builder-grade unit installed to run 275 to 450 dollars. Midrange models, three-quarter horsepower with better sound damping and stainless internals, typically land between 425 and 650 dollars installed. Premium one horsepower units with anti-vibration mounts and longer warranties can reach 700 to 1,000 dollars depending on electrical needs and access.

Those numbers move based on crawlspace access, sink type, and whether your existing plumbing lines up or needs reconfiguration. Angle stops and dishwasher connections that crumble on touch will add cost. The reason to price-check upfront, and to consider Garbage disposal installation Houston providers with clear menu pricing, is to keep small service calls from ballooning. Good shops will ask for photos under your sink before they quote. That courtesy lets them predict the parts they’ll need, which saves you a second visit fee.

A quick field guide to noises, smells, and symptoms

A healthy disposal sounds like a steady hum with a soft grind. Changes in tone tell a story. A loud metallic clatter means a foreign object is bouncing around the chamber. Turn it off immediately. A low, stuck hum without spinning is a jam. Don’t keep the switch on or you’ll trip the thermal overload. A whine that rises and falls can signal bearings on their way out. Vibrations that rattle the basin point to an unbalanced impeller or a loose mounting ring. A chirp at startup sometimes comes from a failing start capacitor on certain models, though many household disposals use simple induction motors without external capacitors.

Smells that persist after a good flush usually live in the splash guard. Pull it, soak it in a mild vinegar solution, and scrub. If odor remains, you might have a film of grease in the trap or a partial clog beyond the trap that grows bacteria. In humid Houston, that biofilm blooms fast, especially in homes where the dishwasher drain ties in at a tee that enables backwash into the disposal. A professional cleaning with a helical drain cable and a degreasing agent can reset the system without harsh chemicals that damage seals.

Water leaking from the bottom of the unit almost always means internal seals have failed. That’s replacement territory. Leaks at the top, around the sink flange, are often fixable by reseating and resealing with plumber’s putty and tightening the mounting assembly. Leaks at the dishwasher hose or discharge elbow usually require a new clamp, a fresh gasket, or simply trimming back a hardened section of hose and refitting it.

When to call for Garbage disposal repair and when not to

DIY has a place. So does restraint. If the disposal hums but doesn’t spin, switch it off, unplug it or cut power at the breaker, and use the hex key that came with the unit to turn the flywheel from the bottom center. Most brands use a 1/4 inch hex. Work it back and forth, clear debris with tongs from the top, never your fingers, then press the small red reset button on the bottom. Restore power and test with cold water. This solves many jams caused by a stray bottle cap or fibrous food.

If the unit trips the breaker repeatedly, smells like burnt electrical windings, or leaks from the body, don’t chase it. That’s money better spent on replacement. If you hear grinding that doesn’t clear with a careful inspection and the tool, stop. Continued operation can score the grind ring and crack the housing.

Homeowners sometimes think a slow drain is a disposal problem. Often, it’s the opposite. The disposal grinds fine but the downstream pipes narrow with grease and soap scum. Snaking the line and restoring proper slope in sagging sections does more for performance than a new motor ever could. In older bungalows, I’ve pulled out trap arms that were half closed by a thick waxy coating. No machine chews its way past that.

Installation choices that pay you back later

If you’re building or remodeling, decide early whether to wire the disposal to a wall switch or use an air switch mounted on the countertop. Air switches cost a little more but resist moisture problems. Place a GFCI-protected outlet in the sink base with a neat drip loop in the cord so any condensation falls away from the receptacle. Use stainless steel mounting hardware. It resists the oxidation that plagues coastal and humid environments, and Houston counts.

Choose a disposal that matches your household’s habits. A serious home cook who preps large batches benefits from a three-quarter horsepower model with stainless grind components and sound insulation. Households that run the dishwasher nightly should prioritize a unit with a robust dishwasher inlet design to disposal impeller replacement prevent backflow and reduce cross contamination of debris. If you often entertain, consider the top-end model once and avoid midlife upgrades after two or three football seasons and crawfish boils.

A small but meaningful installation detail is the alignment of the discharge elbow to the trap. Keep the outlet height equal to or slightly above the trap arm centerline. If you drop too low, you create a belly where slurry settles. Seal the sink flange with a firm bead of plumber’s putty, not silicone, so you can service it later without chiseling. Torque the mounting ring evenly and then recheck after a few days. Thermal cycles and vibration can relax the connection slightly.

Water, grease, and the rhythm of cleanup

Most disposal headaches start after big meals. The sink fills with plates, and someone scrapes everything into the drain at once. This overload starves the motor of torque and sends partially ground scraps into the line. Develop a rhythm. Rinse and grind as you go. Alternate water and scraps in small batches so the chamber clears between loads. Pour pan grease into a disposable container, wipe the skillet with a paper towel, then wash. Even a quarter cup of fat makes a difference once it cools in the lateral that crosses your slab.

If you batch-cook on Sundays, finish with a full-sink flush. Use cold water, a little dish soap, and a 15 second run after the last bit clears. That last step is cheap insurance. In the summer months, when the garage sits at 100 degrees and the house is at 72, temperature swings encourage condensation on cold pipes. Thin films of water collect dust and grease and form a sticky skin. Keeping the line free of residue lowers the chance of that buildup.

The truth about ice, citrus, and cleaners

You’ll hear competing advice about ice cubes. They do not sharpen the grind ring, but they can knock debris off the impellers and clean the chamber walls. If you use ice, feed a small handful with cold water, not rock salt. The salt isn’t necessary and it corrodes mounting hardware over time. Citrus peels are fine in moderation, cut small, and ground with lots of water. They freshen the kitchen more than they sanitize the machine.

Avoid harsh drain cleaners in a disposal. Caustics damage rubber components and can back up into the dishwasher line, ruining hoses. Enzyme cleaners can help with biofilm, but they are slow. A professional hydro-scrub or cable cleaning provides immediate results when you have a sluggish line.

Seasonal realities in Houston homes

Hurricane season brings power outages. A jam right when the lights come back on is common because people forget the switch was left on. When power returns, the motor tries to start under load and trips the thermal protector. Build a habit of switching the unit off at the wall when the power flickers. After an outage, check under the sink for leaks too. Pressure fluctuations can loosen old clamps.

In older houses with pier-and-beam foundations, seasonal movement can tweak the trap alignment just enough to cause slow drainage or a small drip. A quick spring and fall check under the sink saves you a weekend call. Feel for moisture around joints and look for mineral tracks that signal a slow leak.

What a good service call looks like

A reliable provider of Garbage disposal repair should do more than just clear a jam. Expect them to inspect the splash guard, check the mounting ring, verify that the discharge alignment is correct, and test for backflow from the dishwasher line. They should run the unit with a load, not just a quick flip without water. If they recommend replacement, they should explain why in plain terms and show you the failure, whether it’s a cracked housing, rusted bearings, or a burned winding.

For a clean installation from a reputable Garbage disposal installation Houston tech, look for a tidy cord management, a drip loop, new gaskets where appropriate, and a written warranty that covers both the unit and the labor for at least a year. Good shops label the breaker on the panel if it wasn’t already, a courtesy that spares you time later.

Small tools and spares worth keeping

Keep the manufacturer’s hex key taped inside the sink base. A flashlight and a pair of long tongs or needle-nose pliers live there too. A spare splash guard insert that fits your brand is handy, since they crack and stiffen with age. A roll of Teflon tape and a few stainless worm-drive clamps cover most hose connection surprises. None of these items cost much, and they turn a potential evening emergency into a five-minute fix.

Comparing repair versus replacement

There’s a point where repair doesn’t pencil out. If your unit is older than eight years, noisy, and leaking from the body, replacement is the sensible choice. If the motor runs but stalls under light load and you have an undersized model in a busy kitchen, you’re chasing a problem that will return. Upgrading to a better motor with stainless grinding components and an insulated shell reduces noise and extends life. On the other hand, if the unit is relatively new and the trouble is a jam or a leak at the flange, repair is the cost-effective move.

The calculus includes the state of your drain line. If a tech quotes you a disposal replacement but ignores a trap arm packed with sludge, you’ll be calling them back in a week. Ask them to open the trap and show you the condition inside. A transparent diagnosis builds trust and avoids repeat service fees.

A realistic maintenance cadence

- Weekly: Rinse and run with cold water and a few drops of dish soap. Lift and scrub the splash guard.

- Monthly: Do a full-sink flush. Check under-sink joints for moisture. Confirm the mounting ring is tight.

- Seasonally: Inspect the dishwasher hose connection. Verify the air gap or high loop is in place to prevent backflow. Listen for changes in noise or vibration.

Stick to this cadence and you reduce the odds of sudden failure. I’ve seen units last fifteen years with this care, even in heavy-use kitchens.

When you rent versus when you own

Renters should report disposal issues early. Landlords prefer small maintenance visits over water damage claims. Don’t use chemical drain cleaners in a rental; if something goes wrong, you may be held responsible for damaged seals. If the unit jams, try the reset and hex key if available, but avoid disassembling the trap unless your lease allows tenant maintenance. Owners, on the other hand, benefit from learning the basics. A careful trap removal, cleaned and reassembled with new washers, is within reach for most people and solves many “bad disposal” complaints that are really drain issues.

Red flags that raise your costs

If your disposal vibrates so much that the sink deck shudders, the mounting ring may be loose or the impeller assembly bent. Running it in that state shortens the life of both the unit and the sink seal. If the dishwasher leaves gritty residue on the top rack after you run the disposal, you may have backflow or a partially obstructed tie-in that needs attention. If flipping the switch dims the kitchen lights, that circuit is overloaded, and you should call an electrician before the motor suffers damage.

Finally, any scorch smell from under the sink is a hard stop. Unplug the unit. Do not “see if it clears.” Motors that have overheated enough to produce a smell are at the end of their useful life or have a wiring fault that could escalate.

The quiet payoff of better habits

Avoiding costly repair isn’t just about saving a few hundred dollars on a service call. It’s about the knock-on effects. A clean, well-installed disposal keeps the dishwasher draining properly, reduces fruit flies, and keeps the P-trap from becoming a grease museum. Pan grease in the trash instead of the drain spares your lateral and the city’s lines. When everyone on a block builds better habits, municipal backups drop, which you notice when the stormwater mixed with sewer doesn’t burp into your street after a hard rain.

The best feedback you can give your future self is a disposal that fades into the background again. Choose a model that matches your kitchen, install it with care or hire someone who will, feed it wisely, and give it water. Small decisions at the sink keep you out of the emergency lane and in the realm of routine, Affordable Garbage disposal repair rather than full replacements.

And if it’s time for a new unit, don’t hesitate to call a seasoned pro for Garbage disposal installation Houston residents trust. A good installer is less expensive than a second service call, and the right setup pays you back every day you cook, rinse, and flip that quiet little switch without a second thought.

DYZ Plumbing, LLC

Address: 1220 Blalock Rd, Houston, TX 77055

Phone: (832) 877-9600